Professional Sandblasting Equipment & Industrial Sandblasters For Sale

Whether you’re searching for a commercial sandblaster for industrial applications or a portable sand blaster for sale for smaller projects, the quality of your sandblasting equipment directly impacts your results. At N.T. Ruddock Company, we offer professional-grade industrial sandblasting equipment designed to deliver precision, efficiency, and reliability across all applications.

From compact blast cabinets to heavy-duty industrial sand blasters, our comprehensive selection ensures you have the right tools for every blasting job. We’re committed to providing top-quality sandblasters for sale with expert support to help you tackle any project with confidence.

Complete Sandblasting Equipment Selection

Abrasive Blaster Pots – Portable Sand Blasting Equipment

Abrasive blaster pots are essential portable sandblasting equipment perfect for small jobs or restricted spaces where larger sand blasting machines cannot access. These pressurized tanks deliver controlled amounts of blasting media into the main line, offering flexibility and precision for various applications.

Key Features of Abrasive Blaster Pots:

- Portable design for job site mobility

- Adjustable abrasive flow for precise control

- Ideal for confined spaces and detailed work

- Compatible with wet blasting applications

- Various sizes to match compressor air volume

Wet Blasting Capability: Abrasive blaster pots excel in wet blasting operations where abrasive material is mixed with water or liquid to create a slurry. This method reduces dust and heat generation while providing excellent surface preparation results. Best Applications:

- Small to medium surface preparation projects

- Remote job sites requiring portable equipment

- Maintenance and repair operations

- Automotive restoration work

- Detailed cleaning in tight spaces

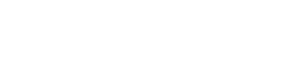

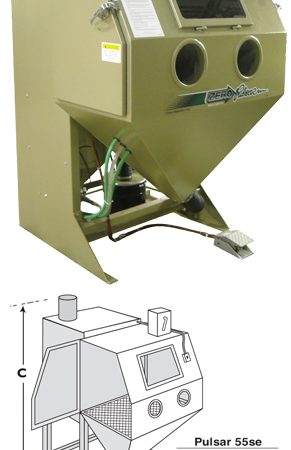

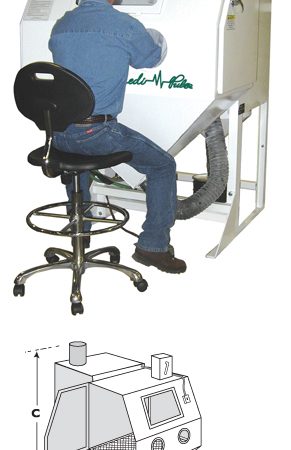

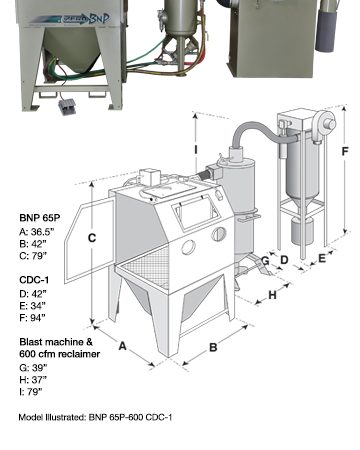

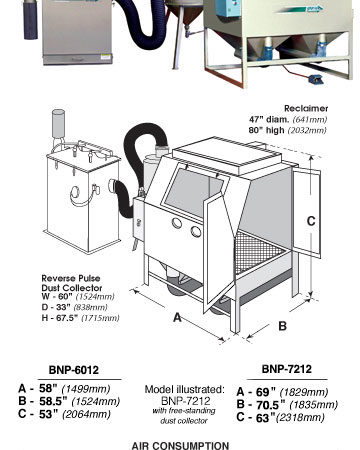

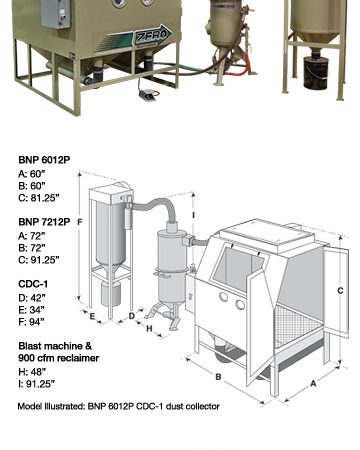

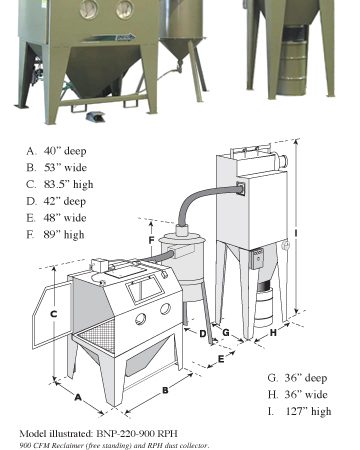

Zero Blast Cabinets

Zero blast cabinets are closed-loop sandblasting equipment systems that recycle the abrasive material used to sandblast the part. They also contain the dust that comes from sandblasting the part. Each cabinet consists of four primary parts:

- The cabinet, which serves as containment

- The abrasive blasting system

- The recycling system for the abrasive

- The dust collection system

These four components work together to blast the part, recycle the abrasive, and keep the dust contained. The operator uses the blast cabinet with gloves attached to the cabinet. These gloves allow the operator to blast the part safely, protecting the operator from the abrasive and dust. The three types of sand blast cabinets available are the siphon blast system, pressure blast system, and the wet blast cabinet. The siphon blast system creates a vacuum with compressed air, pulling the abrasive into the blast gun and through the nozzle. The pressure blast system pressurizes a vessel containing the abrasive, which is attached to the blast hose and nozzle. The abrasive is metered through the hose and nozzle. The wet blast cabinet injects the slurry into a gas stream. A wet cabinet is used to reduce heat that would occur in dry blasting.

Blast Machines – Heavy-Duty Industrial Sandblasters

Blast machines are powerful industrial sandblasters designed for larger-scale projects requiring portable sandblasting equipment with enhanced capacity. When abrasive blaster pots are insufficient but full bulk blaster systems aren’t necessary, blast machines provide the perfect middle-ground solution.

Advantages of Professional Blast Machines:

- Larger capacity than standard blaster pots

- Portable design for job site flexibility

- Operator-controlled abrasive delivery via handle-mounted controls

- Automatic metering into compressed air stream

- Available in multiple sizes and strengths

- Effective for removing corrosion, mill scale, and coatings

Common Applications:

- Structural steel preparation

- Bridge maintenance and restoration

- Tank and vessel cleaning

- Industrial equipment refurbishment

- Large surface area coating removal

- Marine and shipyard operations

Why Choose Blast Machines:

Superior to smaller pots for production work, yet more portable than stationary systems, blast machines deliver industrial sandblasting equipment performance with job site mobility. Available in various configurations to match your specific project requirements and air compressor capacity.

Bulk Blasters – Large-Scale Industrial Sandblasting Equipment

For the most demanding applications, bulk blasters represent the pinnacle of industrial sandblasting equipment. These heavy-duty systems are engineered for large-scale industrial projects where productivity and power are paramount.

Bulk Blaster Configurations:

1. Stationary Systems:

- Permanent installation for high-volume production facilities

- Maximum capacity for continuous operation

- Integrated safety systems and controls

- Ideal for manufacturing plants and large industrial facilities

2. Trailer-Mounted Systems:

- Highway and yard trailer mounting options

- Enhanced mobility for multi-site operations

- Quick setup and breakdown capabilities

- Perfect for contractors and industrial maintenance teams

Safety & Performance Features:

- Advanced safety valves and pressure controls

- Emergency shutdown systems

- Operator protection features

- Designed for intensive commercial sandblaster applications

- Built for extended duty cycles

Best Suited For:

- Power plant maintenance

- Petrochemical facility operations

- Large infrastructure projects

- Shipbuilding and repair

- Heavy industrial manufacturing

- Municipal maintenance operations

Other Sandblasting Equipment

Along with standard stationary and portable sandblasting equipment, we offer specialized and other sandblasting equipment to meet your needs.

Our empire equipment includes a variety of systems and machines to meet your sandblasting equipment needs. We offer batch processing machines, in-line blast systems, continuous processing machines, and more. To learn more about our empire equipment, click here.

Our special application equipment is designed to operate with other sandblasting equipment available. The application equipment includes wet-blast attachments, suction guns, and more.

Choosing the Right Sandblasting Equipment for Your Needs

Selecting the appropriate industrial sandblaster or commercial sandblaster depends on several critical factors:

1. Project Scale & Volume

- Small Projects: Abrasive blaster pots or blast cabinets

- Medium Projects: Blast machines or portable systems

- Large Industrial Projects: Bulk blasters or empire equipment

2. Portability Requirements

- Stationary: Blast cabinets, permanent bulk systems

- Portable: Blaster pots, blast machines

- Mobile: Trailer-mounted bulk blasters

3. Production Environment

- Workshop/Indoor: Sand blast cabinets with dust collection

- Job Site/Outdoor: Portable blast machines, blaster pots

- Manufacturing Floor: In-line systems, batch processors

4. Surface Sensitivity

- Delicate Surfaces: Wet blast cabinets, controlled pressure systems

- Heavy-Duty Removal: Pressure blast systems, bulk blasters

- General Purpose: Siphon or pressure blast cabinets

5. Budget Considerations

- Entry-Level: Siphon blast cabinets, small blaster pots

- Mid-Range: Pressure blast systems, blast machines

- Industrial-Grade: Bulk blasters, empire equipment systems

Why Buy Sandblasting Equipment from N.T. Ruddock?

Comprehensive Selection

We offer the complete spectrum of sandblasting equipment from portable sandblasters for sale to heavy-duty industrial sandblasting equipment. Whatever your application, we have the right solution.

Expert Technical Support

Our knowledgeable team provides guidance on equipment selection, setup, operation, and maintenance. We ensure you choose the right sand blasting machine for your specific needs.

Quality Assurance

Every commercial sandblaster and piece of equipment we offer meets rigorous quality standards. We stand behind our products with comprehensive warranties and support.

Parts & Service

Complete parts inventory and service support keep your sandblasting equipment operating at peak performance. Fast shipping ensures minimal downtime.

Competitive Pricing

Professional-grade industrial sandblasters for sale at competitive prices. We work with your budget to provide maximum value without compromising quality.

Sandblasting Equipment Buying Guide

Questions to Ask Before Purchasing:

1. What materials will you be blasting?

Different surfaces require specific equipment types and abrasive media compatibility.

2. What is your available air supply?

Compressor CFM and PSI determine which sandblasting equipment will operate effectively.

3. How often will you use the equipment?

Daily production use requires different equipment than occasional maintenance work.

4. What is your workspace like?

Available space influences whether blast cabinets or portable systems work best.

5. Do you need dust containment?

Indoor operations typically require enclosed systems with dust collection.

6. What is your production volume?

Higher volumes justify investment in automated or high-capacity systems.

Sandblasting Equipment Maintenance & Support

Maximizing Equipment Life

Proper maintenance ensures your industrial sandblasting equipment delivers reliable performance for years:

- Regular inspection of hoses, nozzles, and seals

- Moisture separator maintenance for air quality

- Dust collector filter changes on schedule

- Abrasive media quality monitoring

- Pressure vessel inspections per regulations

- Lubrication of moving components

Parts & Service Availability

N.T. Ruddock maintains extensive parts inventory for all sandblasting equipment we sell:

- OEM replacement parts

- Upgrade components

- Consumable supplies (nozzles, hoses, seals)

- Safety equipment and PPE

- Blast media and abrasives

Industries We Serve with Sandblasting Equipment

Our commercial sandblaster and industrial sandblasting equipment solutions serve diverse industries:

- Manufacturing: Production line integration, batch processing

- Automotive: Restoration, parts cleaning, surface preparation

- Aerospace: Component preparation, coating removal

- Marine: Hull maintenance, deck preparation, rust removal

- Construction: Structural steel preparation, concrete surface prep

- Oil & Gas: Pipeline maintenance, tank cleaning, equipment refurbishment

- Railroads: Railcar restoration, component refurbishment

- Municipal: Infrastructure maintenance, equipment restoration

- Fabrication: Metal preparation, weld cleaning, part finishing

Frequently Asked Questions About Sandblasting Equipment

What size industrial sandblaster do I need?

Size depends on your compressor capacity (CFM), project scale, and production requirements. Contact our experts for a recommendation based on your specific application.

What’s the difference between a blast cabinet and a blast machine?

Blast cabinets are enclosed systems with dust collection and media recycling, ideal for workshops. Blast machines are portable, open-blasting systems for job sites and large surfaces.

Can I use different abrasive media in the same equipment?

Yes, most sandblasting equipment can handle multiple media types. However, media should be compatible with nozzle size and system pressure ratings.

How much air pressure do I need for sandblasting?

Most systems require 80-120 PSI with sufficient CFM volume. Specific requirements vary by equipment type and nozzle size. Always match equipment to your compressor specifications.

Are sandblasters for sale expensive to operate?

Operating costs depend on media consumption, media recyclability, and energy usage. Pressure systems with media recycling offer the lowest cost per part over time.

What safety equipment is needed for sandblasting?

Required safety gear includes: respiratory protection, protective clothing, hearing protection, and proper ventilation. Enclosed systems like blast cabinets reduce PPE requirements.

Do you offer training on sandblasting equipment?

Yes, we provide operator training and technical support for all industrial sandblasting equipment we sell. Contact us for training options.

What warranty comes with your sandblasters?

Warranty coverage varies by manufacturer and equipment type. Contact us for specific warranty details on any sand blasting machine or system.

Request a Quote or Expert Consultation

Ready to invest in professional sandblasting equipment? Our team is here to help you select the perfect industrial sandblaster, commercial sandblaster, or specialized system for your application.

Contact N.T. Ruddock Today:

- Discuss your project requirements with experts

- Get personalized equipment recommendations

- Receive detailed quotes on sandblasters for sale

- Learn about financing and delivery options

- Schedule equipment demonstrations