Sandblasting Equipment

No matter your skill level, the quality of your results depends heavily on the sandblasting equipment you use. Having the right tools in place ensures a strong starting point for any blasting job. The right sandblasting equipment can mean the difference between a successful project and potential damage to the surface you’re working on. At N.T. Ruddock Company, we’re committed to providing top-quality sandblasting equipment to help you tackle any job with confidence and precision.

Abrasive Blaster Pots

Abrasive blaster pots are part of sandblasting equipment that is portable. They are effective for small jobs or jobs in restrictive spaces that larger equipment can’t access. These blast pots are pressurized tanks that allow blasting grit into the main blasting line. One of the advantages of abrasive blaster pots is that the abrasive material in the pots can be adjusted to the correct amount delivered into the main blasting line. Abrasive blaster pots vary in size, and the number of pots required for a job depends on the volume of air from the compressor. Abrasive blaster pots are also used in wet blasting. In wet blasting, the abrasive is mixed with water or some other liquid to create a slurry. This slurry is used in the same way the stream of air with grit is used.

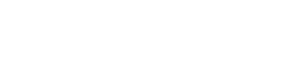

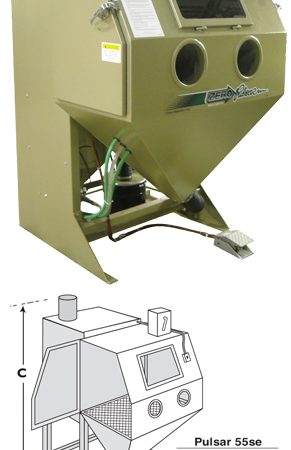

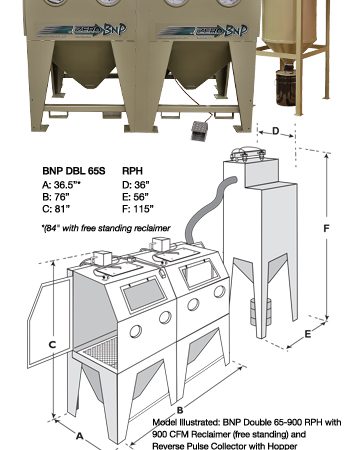

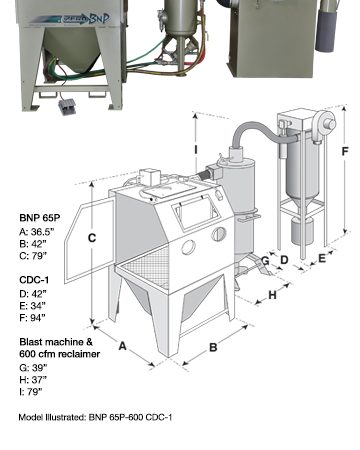

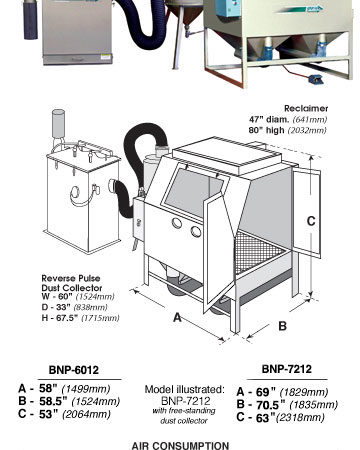

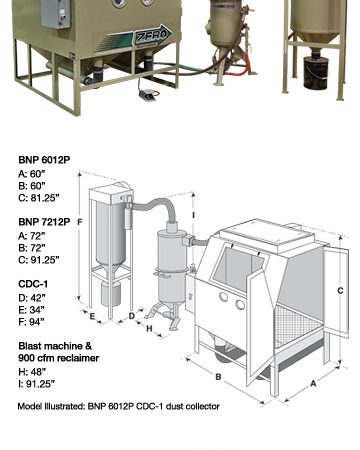

Zero Blast Cabinets

Zero blast cabinets are closed-loop sandblasting equipment systems that recycle the abrasive material used to sandblast the part. They also contain the dust that comes from sandblasting the part. Each cabinet consists of four primary parts:

- The cabinet, which serves as containment

- The abrasive blasting system

- The recycling system for the abrasive

- The dust collection system

These four components work together to blast the part, recycle the abrasive, and keep the dust contained. The operator uses the blast cabinet with gloves attached to the cabinet. These gloves allow the operator to blast the part safely, protecting the operator from the abrasive and dust. The three types of sand blast cabinets available are the siphon blast system, pressure blast system, and the wet blast cabinet. The siphon blast system creates a vacuum with compressed air, pulling the abrasive into the blast gun and through the nozzle. The pressure blast system pressurizes a vessel containing the abrasive, which is attached to the blast hose and nozzle. The abrasive is metered through the hose and nozzle. The wet blast cabinet injects the slurry into a gas stream. A wet cabinet is used to reduce heat that would occur in dry blasting.

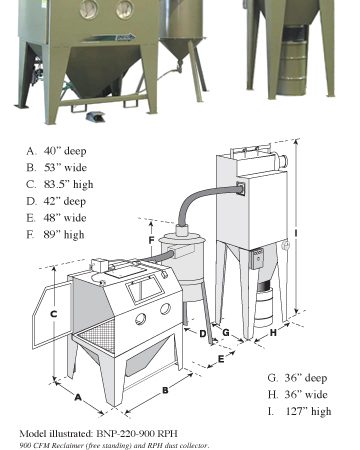

Blast Machines

Blast machines operate similarly to abrasive blaster pots. However, blast machines are bigger than pots, allowing for use with larger jobs to remove corrosion, mill scale, and coatings from most surfaces. When using a blast machine, the operator controls the abrasive using a handle at the nozzle. The abrasive is automatically metered into the compressed air stream. Blast machines are effective when portable sandblasting equipment is needed, but abrasive blast pots are insufficient. Blast machines are portable, which makes it easier to move them, and they come in different sizes and strengths to match your sand blasting sand needs.

Bulk Blasters

When you need sandblasting equipment for very large jobs, bulk blasters are an excellent option. Larger than blast machines, bulk blasters are designed for large-scale and industrial sandblasting sand jobs. Bulk blasters are available as either stationary or with the ability to be mounted on highway and yard trailers, which makes them easier to move around a job site. Bulk blasters include safety features and valves to ensure safe, effective operation when sandblasting.

Other Sandblasting Equipment

Along with standard stationary and portable sandblasting equipment, we offer specialized and other sandblasting equipment to meet your needs.

Our empire equipment includes a variety of systems and machines to meet your sandblasting equipment needs. We offer batch processing machines, in-line blast systems, continuous processing machines, and more. To learn more about our empire equipment, click here.

Our special application equipment is designed to operate with other sandblasting equipment available. The application equipment includes wet-blast attachments, suction guns, and more.

If you have any questions about our blasting equipment and how it can help you, please contact us and we will be happy to help you.