Sandblasting Rooms

Safety

Preassembled blast rooms are designed with a focus on safety to provide a controlled and secure environment for abrasive blasting processes. However, safety ultimately depends on proper installation, maintenance, and adherence to operational guidelines. Here are some factors that contribute to the safety of preassembled blast rooms: Ventilation Systems: Adequate ventilation is crucial to control dust and fumes generated during the abrasive blasting process. Preassembled blast rooms typically include well-designed ventilation systems and dust collection units to ensure a safe working environment. Operator Safety Measures: These blast rooms often incorporate safety features such as emergency shutdown controls, interlocks, and personal protective equipment (PPE) requirements for operators. Training and adherence to safety protocols are essential for those working inside the blast room. Lighting: Proper illumination is critical for the safety and accuracy of abrasive blasting operations. Preassembled blast rooms typically include specialized lighting systems to enhance visibility and prevent accidents. Access Doors: Large access doors are designed for easy entry and exit of workpieces, but they also serve as safety features. Emergency exits and quick egress points are often incorporated into the design to ensure the safety of personnel in case of an emergency. Compliance with Standards: Reputable manufacturers design preassembled blast rooms to meet industry standards and regulations regarding safety, environmental impact, and worker health. Compliance with these standards helps ensure that the equipment is built with safety in mind. Turnkey Solutions: Many preassembled blast rooms are offered as complete, turnkey solutions. This means that the entire system, including safety features and operational controls, is integrated and tested by the manufacturer before installation, reducing the likelihood of safety issues resulting from poor integration or component compatibility. It’s important for operators and facility managers to follow manufacturer guidelines, conduct regular maintenance, and provide proper training for personnel working in or around preassembled blast rooms. When used and maintained correctly, preassembled blast rooms can provide a safe and controlled environment for abrasive blasting processes.

Reliability and Uptime

The reliability of a blast room is crucial for ensuring efficient and safe operations. Here are several aspects to consider when discussing blast room reliability:

Equipment Quality:

The reliability of a blast room heavily depends on the quality of the equipment used. High-quality blasting machines, abrasive recovery systems, and dust collection systems contribute to the overall dependability of the blast room.

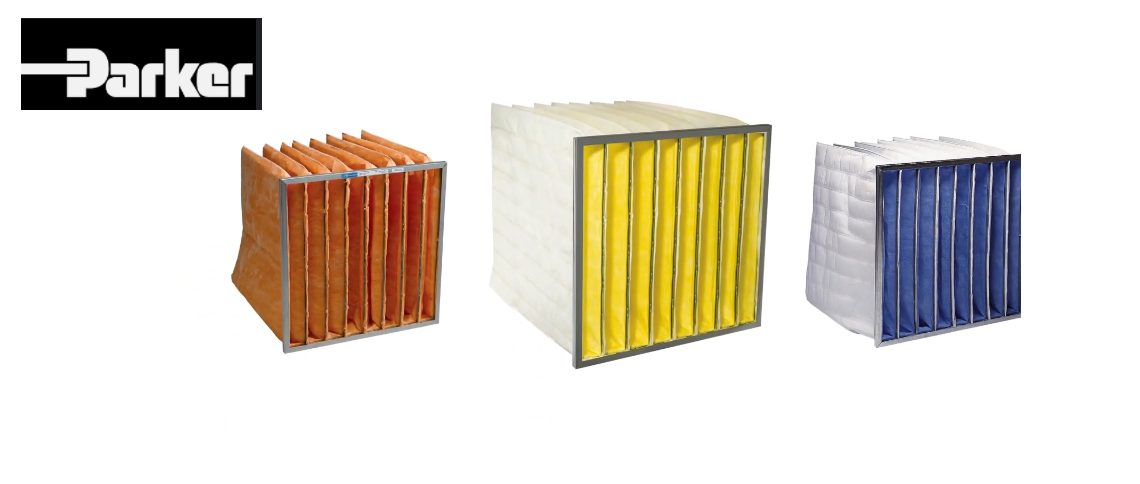

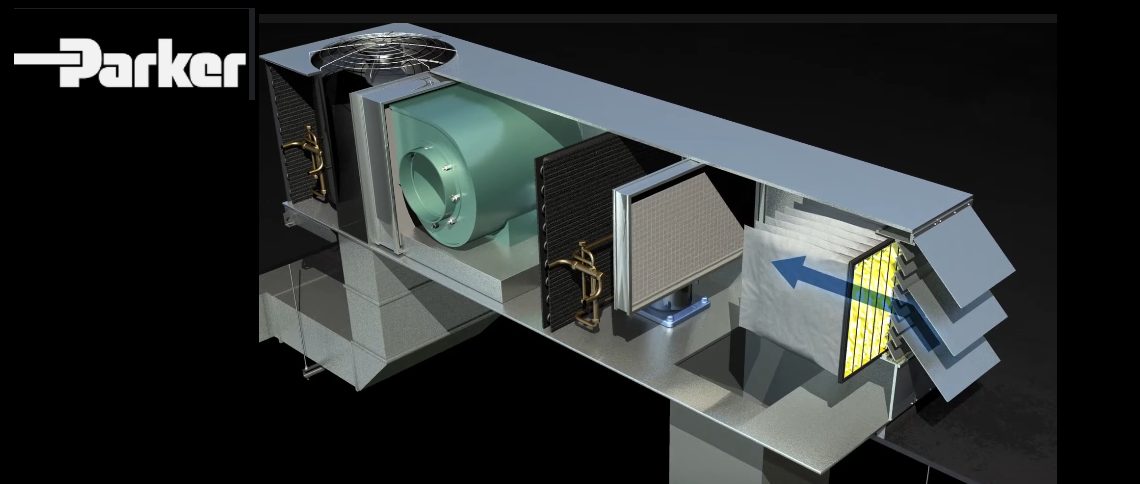

Ventilation and Dust Collection:

Adequate ventilation and dust collection systems are essential for maintaining a clean and safe working environment. Reliable dust collection systems prevent the accumulation of abrasive dust, protecting both equipment and workers from potential hazards.

Material Handling Systems:

Efficient material handling systems, including conveyor belts and transfer mechanisms, contribute to the reliability of the blast room. These systems must be durable and designed to handle the specific requirements of the materials being processed.

Safety Features:

A reliable blast room should be equipped with robust safety features, including emergency shutdown mechanisms, proper lighting, and safety interlocks. These features are critical for protecting workers and preventing accidents.

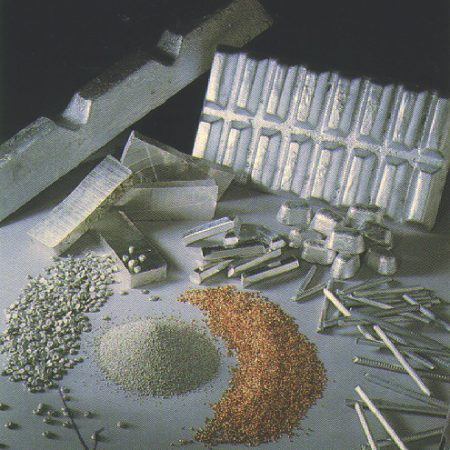

Abrasive Media Recycling:

Blast rooms often incorporate abrasive media recycling systems to maximize efficiency and reduce costs. The reliability of these systems is crucial for maintaining a continuous and consistent blasting process.

Structural Integrity:

The structural integrity of the blast room itself is vital for long-term reliability. The room should be constructed with durable materials capable of withstanding the abrasive blasting process without deterioration or compromise.

Maintenance Protocols:

HEPA breathing filters need to be serviced to manufacturer specifications and blast masks to OSHA standards. Not adhering OSHA standards and breathing air quality for employee safety will result in a shut-down. Establishing regular maintenance protocols is essential for ensuring the ongoing reliability of a blast room. This includes routine inspections, equipment checks, and preventive maintenance to address potential issues before they lead to downtime.

Operator Training:

Operator competence contributes significantly to the reliability of a blast room. Proper training ensures that operators understand the equipment, follow safety protocols, and can troubleshoot minor issues, minimizing the risk of downtime due to operator error. Compliance with Regulations: Compliance with industry regulations and safety standards is critical for the overall reliability of a blast room. Ensuring that the facility meets or exceeds regulatory requirements contributes to a safe and reliable working environment.

Monitoring and Control Systems:

Advanced monitoring and control systems enhance the reliability of blast rooms by providing real-time data on process parameters. These systems allow operators to make adjustments as needed, ensuring consistent and efficient blasting operations. In summary, blast room reliability is a multifaceted concept that encompasses the quality of equipment, safety features, structural integrity, maintenance practices, and operator training. A well-designed and properly maintained blast room is essential for achieving consistent and reliable abrasive blasting processes in industrial settings.

Benefits of Buying a New Blast Room

Deciding between a new or used abrasive blast room involves considering several factors, and each option comes with its own set of advantages and potential drawbacks. New blast rooms often incorporate the latest technological advancements and features. This can include improved abrasive recovery systems, more efficient dust collection systems, advanced control interfaces, and other innovations that enhance overall performance and productivity. When purchasing a new abrasive blast room, you have the opportunity to customize the system to meet your specific requirements. This includes selecting the size, features, and configurations that best suit your applications. Customization ensures that the blast room is optimized for your unique needs. New equipment typically comes with a warranty, providing assurance that the manufacturer stands behind the product. This can be crucial for addressing any potential issues that may arise shortly after installation. Additionally, manufacturers of new equipment often offer comprehensive customer support and maintenance services. New blast rooms are designed to meet or exceed current industry standards and regulations. This is especially important for ensuring a safe working environment and compliance with environmental and safety requirements. Up-to-date equipment is more likely to meet the latest standards than older, used equipment. New equipment tends to have a longer lifespan compared to used machinery. The components are fresh, and the materials are less likely to have experienced wear and tear. Investing in new equipment can offer a more extended period of reliable service before major overhauls or replacements are needed. Newer blast rooms often incorporate energy-efficient technologies, leading to cost savings over the long term. Improved efficiency can result in reduced abrasive consumption, lower energy costs, and better overall process performance. New equipment is less likely to experience unexpected breakdowns or require frequent repairs, leading to reduced downtime. This can be particularly important in industries where continuous operation is critical to meeting production schedules. While there are clear benefits to buying a new abrasive blast room, it’s important to note that budget constraints and specific operational needs may make used equipment a viable option for some businesses. When considering a purchase, it’s essential to carefully evaluate both new and used options based on factors such as your budget, production requirements, and the condition of the used equipment.